J-tech Center

What is J-tech Center?

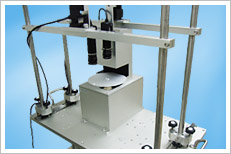

J-tech Center is a showroom where JEL main robots or Bernoulli end-effector are on display.

Operation check using customers’ wafer is available with prior arrangement.

Also, we offer robot training using actual robot.

How to use J-tech Center?

- Vacuum check for Bernoulli

end-effector

Vacuum check for Bernoulli end-effector is available for 150mm, 200mm, and 300mm wafer.

- Alignment accuracy

test

Alignment accuracy test with the measuring tool is available using customer's wafer.

- Robot operation training

Robot operation training using actual robot is available at J-tech Center.

Contact for application

- Contact

- JEL Corporation Head Office

- Tel

- +81-84-932-6500

Display robots

- MTCR for tape frame for 300mm wafers: MTCR4160-300-AM

- Designed for handling 300 mm wafers in a production line or inspection line of semiconductor. High-speed handling by AC servo motor and superior cost performance compared to MTHR type

- STCR for 150 or 200 mm chemical compound wafer:

STCR4160S-300-PM - Designed for handling small wafers in a production line or inspection line of semiconductor. Base or flange mounting type is selectable.

- Automatic wafer transfer system for wafer container: SSY-10010

- High accuracy transport of thin wafer inside the wafer container. Equipped with mechanism of automatic lid opening/closing of the wafer container. (Patent pending)

- Twin-arm clean robot for handling wafer up to 300mm (Closed-loop control): STCR4160SN-300-CM

- For handling wafers from 2 inch to 300mm with low-cost, high-speed handling, and no step-out error.

- Horizontal and multi-joint type clean robot for handling 300 mm wafers: GCR4210-300-PM

- Designed for handling 300mm wafers in a production line or inspection line of semiconductor.

- Twin-arm clean robot with flip unit & Aligner for handling thin, 150mm and 200mm wafers: STCR4160S-300-PM/SAL3481

- By using our Bernoulli type end-effector, the robot with twin-arm flip unit robot transfers thin, 150mm and 200mm wafers. Aligner are for thin wafers, which can handle 150mm and 200mm wafers. Flip unit is installed at both arms to handle both 150mm and 200mm wafers simultaneously.

- Aligner for handling 2, 3 inch, 100 to 150mm wafer: SAL3261HV

- New type of aligner available for any material of wafer for 2, 3 inch, 100 to 150mm wafer.

- Edge grip aligner for handling 150mm wafer: SAL2061

- High-speed, high-accuracy centering and flat/notch locating of small wafer by edge grip wafer holding.

- Table-top loader system for 100mm wafer: SSY-10000

- Available for various types of wafers; 2, 3 inch, 100mm glass, sapphire, SiC, or GaN or others

- Bernoulli type end-effector for thin or warped wafer

- Low-cost Bernoulli type end-effector available for customization. As an ideal end-effector for thin and warped wafers, we provide the Bernoulli type end-effector at its most suitable design according to the customers’ system layout.