Troubleshooting

Vacuum Troubles

Q1. Solenoid valve does not work.

- A1-1

- Check if the connecting part is not loosened or disconnected. Check if VAC and LEAK, AIR and EXH are connected correctly.

- If the connection is wrong or loosened, connect them properly, and check again.

- A1-2

- Check if the robot power is turned ON. Check if the communication with robot is available.

- If the power is OFF, supply the power properly, and check again.

- A1-3

- Check if the operation command is correct.

- Check if the robot can be operated via teaching box.

- If the command is wrong, check the command with the operation manual.

- A1-4

- Check the pressure display on the pressure switch.

- If pressure value changes for ON/OFF, solenoid valve is operating. Check the supply lines to the end-effector.

- If pressure value is not changed regardless of ON/OFF of the solenoid valve, operate the solenoid valve manually. (Refer to the procedures below.)

- *If vacuum line is connected to the vacuum break port (LEAK), not to the vacuum side (VAC), ON/OFF operation becomes reverse.

- *It is the same to the positive pressure specs. If positive pressure line is connected to the break port (EXH), not to the positive pressure port (AIR), ON/OFF operation becomes reverse.

- Procedures for manual operation of solenoid valve

- 1.

- Turn the controller power OFF and disconnect the robot cables.

- 2.

- Remove the cover of the robot driving area (cable connection side). The solenoid valve is installed around the upper part of the cable connection.

- 3.

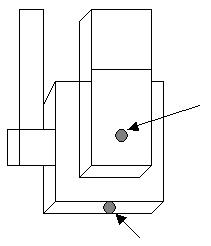

- Small switches are attached on the top and front side of the solenoid valve (See the figure below). You can turn ON/OFF the solenoid valve manually with these switches. After connecting the cables, turn the power ON and press these switches alternately.

Q2. Pressure switch does not work.

- A2-1

- Check if the specified pressure is supplied to the robot.

- If not, connect them properly, and check again. (Refer to the spec book.)

- A2-2

- Check if the pressure supply part is not loosened or disconnected. Check if VAC and LEAK, AIR and EXH are connected correctly.

- If the connection is wrong or loosened, connect them properly, and check again.

- A2-3

- Check if the solenoid valve is operating.

- If not, check the operation according to the procedure“Q1. Solenoid valve is not operating”.

- A2-4

- Check the pressure switch display.

- If it is not displayed, replace the pressure switch.

- A2-5

- Check if the setting of the pressure switch is correct.

- If the setting is wrong, readjust the pressure switch correctly. (Refer to the operation manual.)

- A2-6

- Check if cables between the robot and the controller are not loosened or disconnected.

- If loosened or disconnected, connect them properly and tighten the screw or lock.

- If the connection is correct, replace the pressure switch.

[an error occurred while processing this directive]