JEL dedicated website for SEMICON exhibition robots

|

|

|

|

|

|

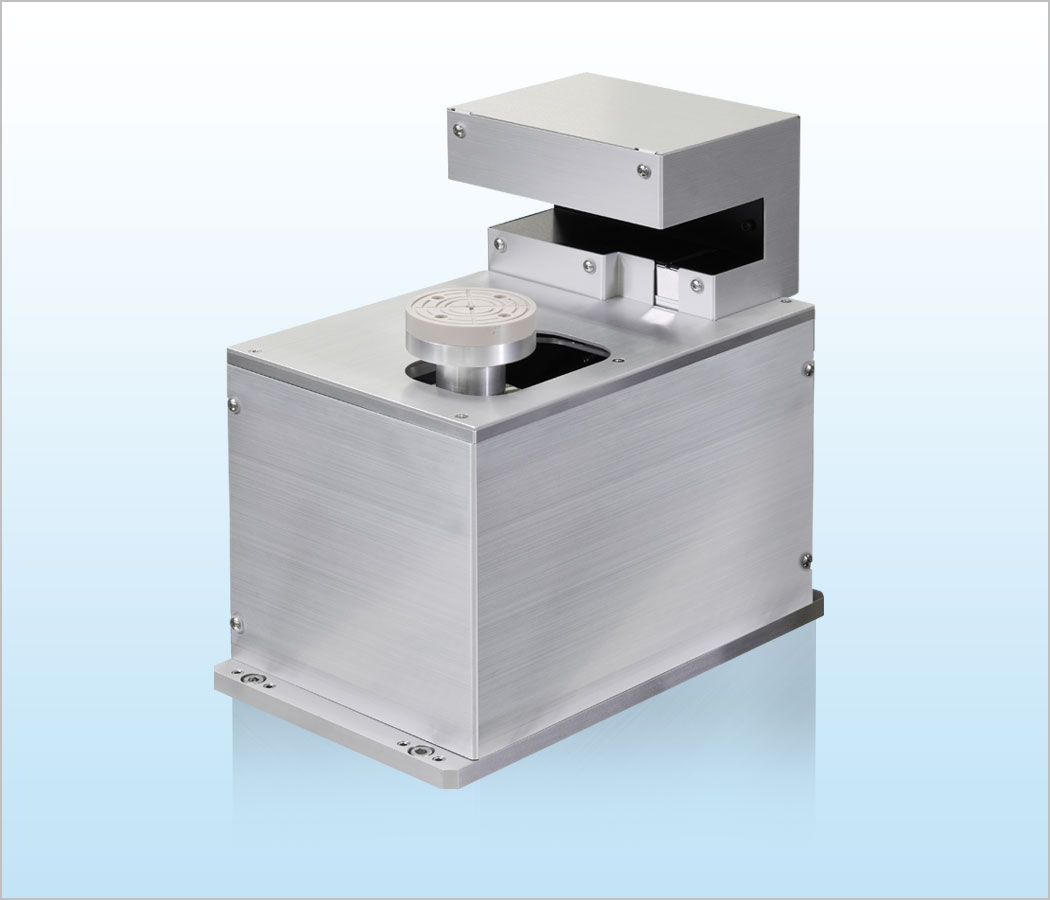

New Aligner "SAL3000HV Series" (Full auto-adjustment version)

New low head SAL-HV (Multi work aligner)Wafer Aligner

Product Video |

Usage Environment/SpecificationsProduct Profile

|

Characteristics

Full auto-adjustment software JEL ALIGN TOOL comes with Aligner SAL3000HV series that have been released on December 14, 2016.

Downtime can be reduced significantly.

*Click to go to the page of New Aligner "SAL3000HV Series" (Full auto-adjustment version)(*).

(*) Please note that this tool (software) is not for guaranteeing the positioning accuracy

after adjustment. Make sure to check the positioning accuracy by using the customer’s

inspection device at customer’s side.

Aligner available for any material of wafer for 200 to 300 mm wafer

- High-speed, high-accuracy centering and flat/notch locating are available for silicon wafer with BG tape as well as silicon, transparent, or translucent wafer.

- Equipped with JEL-developed image sensor, and internal motor driver and controller.

- ウェーハサイズ、材質にあわせて保持方法の変更可能

- Available for non-SEMI standard notch or flat

- ウェーハ持ち直し動作が可能な昇降ユニットをオプションで取付可能

- 多種多様なウェーハのアライメントが可能

Standard Specifications

| Carrying Object | SEMI standard 200 to 300 mm wafer (Transparent, translucent, silicon) |

|---|---|

| Positioning Time | Centering : 1.5 sec (Wafer pick-up/placing time excluded) |

| Positioning Accuracy | Centering: Within ±0.1 mm Flat locating/Notch locating: Within ±0.1 deg |

| Sensor | LED light + wafer edge detection with image sensor unit |

| Wafer Size Change | By command control or switch |

| Cleanliness | ISO Class 2 (at wafer transfer level when exhausting driving part) |

| Driving Method | 2-phase stepping motor (for 3 axes) Internal motor driver, controller |

| Utility | Power: DC24V±10% 3A Vacuum: -53 kPa or more |

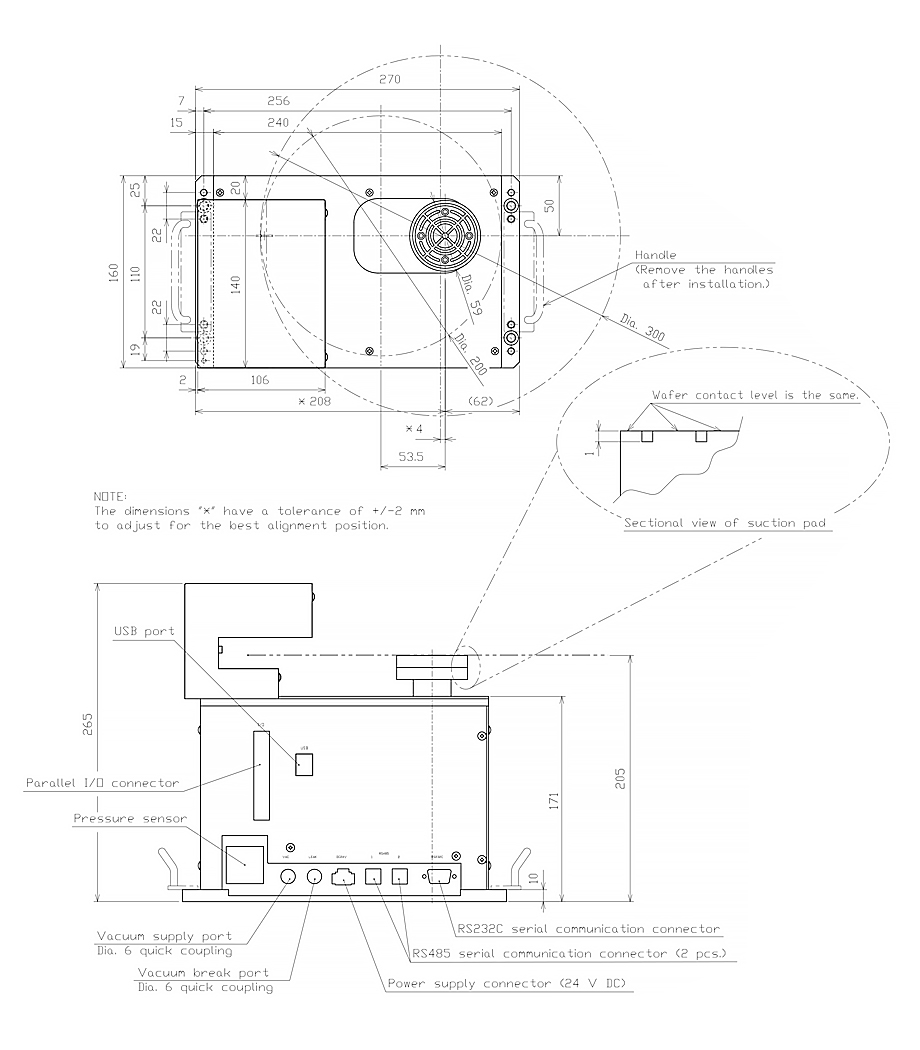

| Outline Drawing |

|---|

|

|

|

|

|

|

|

Icon guide

- ...Atmosphere

- ...Vacuum

- ...Waterproof

- ...Thin wafer

- ...CE marking

- ...JEL's standard spec.

- ...KCs marking