Robot for Semiconductor

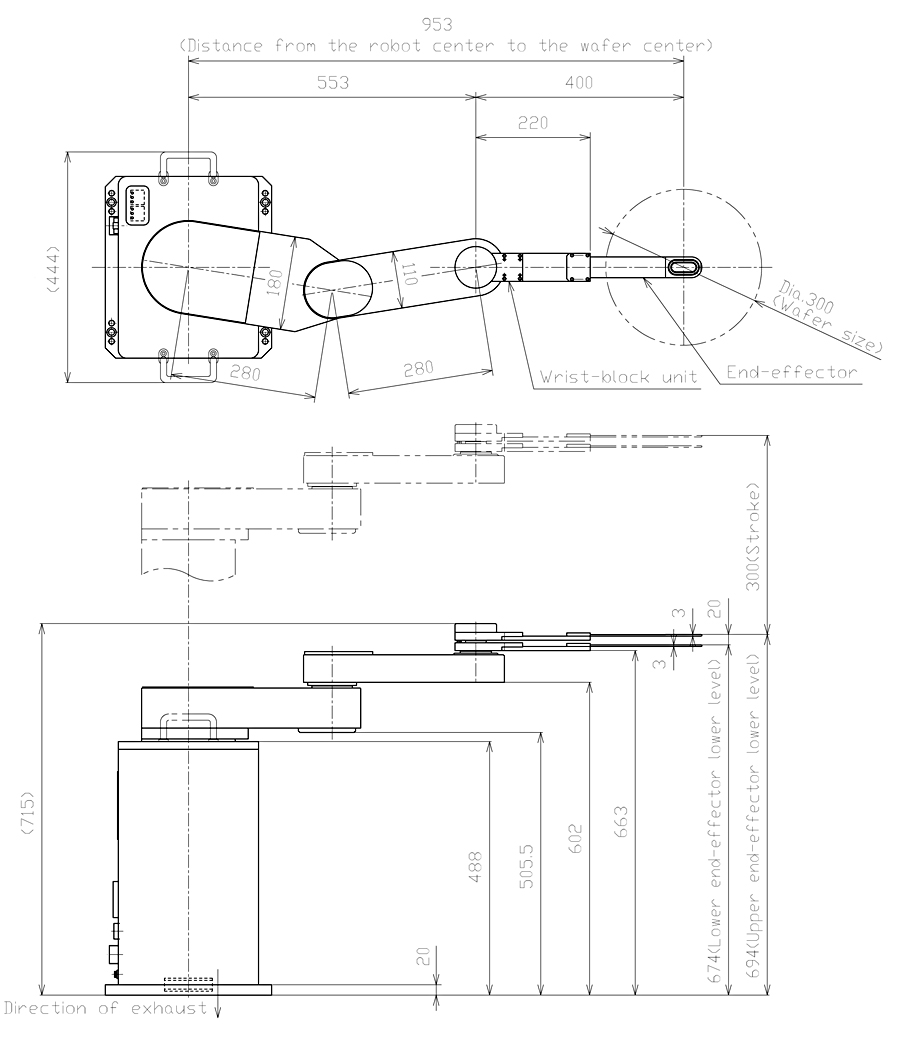

GTCR5280 (For 300mm wafer)5-Axis Horizontal and Multi-Joint Type Clean Robot

Product Video

|

Usage Environment/Specifications

Product Profile

| Model Name | GTCR5280 |

|---|

| Environment | Clean room atmosphere |

|---|

| Arm | Single arm |

|---|

| Operating Range | 553mm (3rd joint center) |

|---|

| Vertical Stroke | 300mm |

|---|

| Payload Capacity | Below 4kg (calculated for the arm 3rd joint) |

|---|

List of Product Model

| Product Model | Vertical Stroke |

|---|

| Standard | GTCR5280-300-AM | 300mm |

- The image above and the video are of GTCR5280-300-AM.

|

Characteristics

A twin end-effector mounted on its single-arm has the same function as a twin-arm robot.

Designed for handling 300mm wafers in a production line or inspection line of semiconductor.

Execution of origin search is not required by using the servo motors with absolute encoders.

- 3 FOUP access is available without a track.

- Twin end-effector reduces the wafer swap time.

- Base or flange mounting type is selectable.

- Motion monitoring is available.

- RS232C and parallel photo I/O are standard for control.

- AC servo motors with absolute encoders installed in all axes.

- High-speed, high-accuracy wafer handling by S-curved speed control and optimizing pass control.

- Wafer holding: end-effector with vacuum suction, passive edge, edge grip, or Bernoulli type End-effector.

- End-effector material: CFRP, Al, ceramic, or others.

- Optimal end-effector is selectable according to the carrying object and line layout.

Standard Specifications

Example of standard specifications with JEL standard end-effector (vacuum type)

| Robot Model |

GTCR5280-300-AM |

| Carrying Object |

Up to 300mm silicon wafer |

| Wafer Holding Method |

By vacuum suction |

| Robot Model Type |

Horizontal and multi-joint type |

Control Axis |

5-axis |

| Motor Type |

AC servo motor |

| Operating Range |

From the robot center to the wafer center |

Rotation Angle (Theta-axis) |

Vertical Stroke (Z-axis) |

| 953mm |

335deg |

300mm |

| Carrying Speed |

Arm (R-axis) |

Rotation Angle (Theta-axis) |

Vertical Stroke (Z-axis) |

| 833mm/sec |

250deg/sec |

300mm/sec |

| Repeatability |

Within ±0.1mm |

| Cleanliness |

ISO Class 2 (at wafer transfer level when exhausting driving part) |

| Utility |

Power: AC200V Single phase ±10% 2kVA; Vacuum: -53kPa or more |

| Mass |

Approx. 50kg |

| Controller Model |

C5000S series |

| Interface |

RS232C and parallel photo I/O |

Option

End-Effector

| Model Name |

Size of Carrying Object |

End-effector Type (Thickness) |

Wafer Holding Method |

| SC-IW-200 |

3 inch, 100mm to 200mm |

I-shape (2mm) |

Vacuum suction |

| SC-IW-240 |

3 inch, 100mm to 300mm |

I-shape (2mm) |

Vacuum suction |

| SC-YW-200 |

100mm to 200mm |

Y-shape (2mm) |

Vacuum suction |

| SC-YW-227 |

100mm to 300mm |

Y-shape (2mm) |

Vacuum suction |

| SC-YW-240 |

100mm to 300mm |

Y-shape (2mm) |

Vacuum suction |

| 3D-02229 |

150mm~300mm |

Y-shape (2mm) |

Vacuum suction |

| SC3-YW-240 |

300mm |

Y-shape (3mm) |

Vacuum suction |

| 3D-01661 |

300mm |

Y-shape (3mm) |

Vacuum suction |

| SC3-IW-240 |

300mm |

I-shape (3mm) |

Vacuum suction |

*The table above shows the specifications of JEL standard end-effectors. The other specifications are available.

*Click the items below to review the end-effectors other than JEL standard types.

Other Option

Product Lineup